Are you struggling to choose the right stepper motor for your industrial application? You are not alone. Selecting the perfect motor goes beyond just checking dimensions; it requires a deep understanding of electronics, torque dynamics, and drive methods.

At HDBMOTOR, we understand that the right motor is the heart of your automation system. Whether you are designing a precision 3D printer or a heavy-duty CNC machine, this guide will walk you through the 7 critical parameters for stepper motor selection.

1. Static Torque: The Foundation of Power

Static torque (or holding torque) is often the first specification engineers look at. It represents the "strength" of the motor when the rotor is stationary and rated current is applied.

Unlike AC or DC motors, a stepper motor's power is defined by its ability to hold a position.

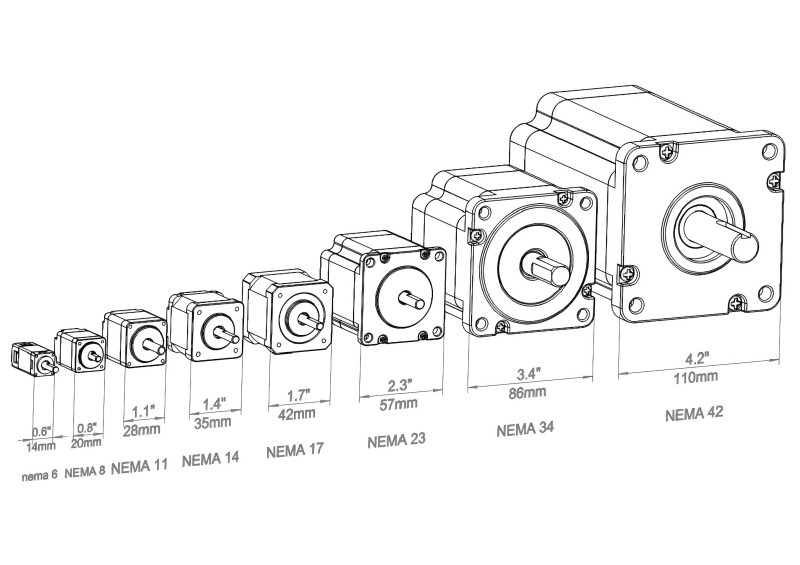

Small Load (< 0.8 N.m): Opt for NEMA 8 to NEMA 17 frame sizes.

Medium Load (~ 1.0 N.m): The NEMA 23 series is the industry standard.

Heavy Load: For high-torque applications, NEMA 34 or NEMA 42 motors from HDBMOTOR are recommended.

2. Drive Methods: Constant Voltage vs. Constant Current

Selecting the motor is only half the battle; the drive method dictates performance.

Constant Voltage Drive: Simple and cost-effective but requires careful resistance matching. Ensure the motor's resistance (usually tens of ohms) limits the current to prevent driver chip damage.

Constant Current Drive (Chopper Drive): Ideal for high-performance applications. It is typically used with low-resistance, high-rated current motors (1-3A). This method maintains torque at higher speeds.

Unipolar vs. Bipolar Drives:

Unipolar: Simpler circuit (4 power tubes), suitable for high-speed applications.

Bipolar: More complex (8 power tubes), utilizing the full winding for higher torque at low speeds. Most modern industrial applications prefer bipolar drives for their efficiency.

3. Drive Voltage: The Speed Factor

Think of drive voltage as the fuel for speed. The input voltage to your driver (e.g., DC 12V, 24V, 48V or AC 110V/220V) directly impacts the motor's high-speed performance.

Rule of Thumb: Higher voltage = Better torque performance at high speeds.

If your machine requires rapid movements, ensure your driver and power supply can handle higher voltages (e.g., upgrading from 12V to 24V or 48V).

4. Drive Current (Phase Current)

Two motors may look identical (same NEMA size) but have vastly different internal windings.

At HDBMOTOR, we offer various resistance and current ratings for the same frame size to match your specific driver costs and performance needs:

Lower Current: Allows for cheaper, simpler drivers but may have higher inductance (lower high-speed torque).

Higher Current: Requires more robust drivers but delivers better dynamic performance.

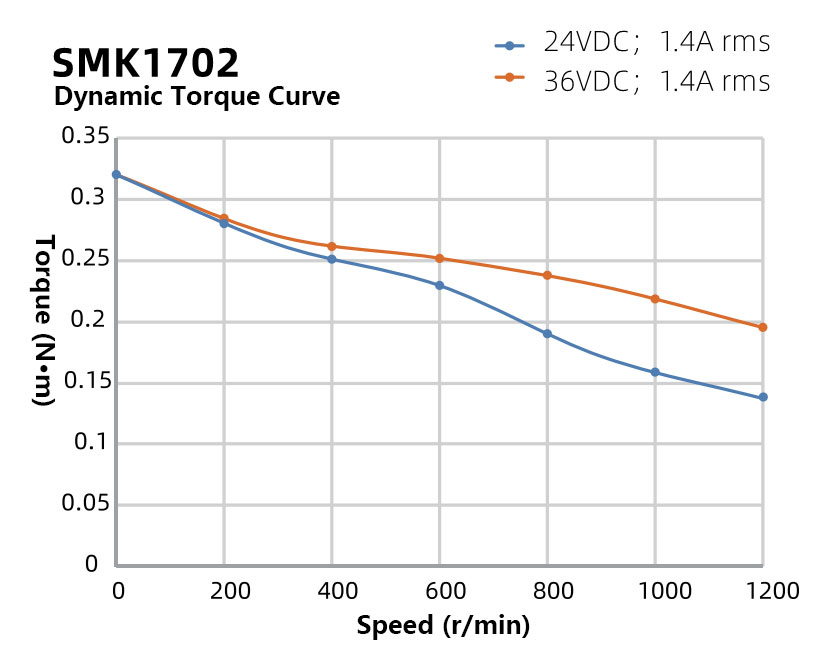

5. Torque-Frequency Characteristics (Speed vs. Torque)

This is the most critical dynamic curve for any engineer.

The Reality: Stepper motors produce maximum torque at low speeds. As speed increases, torque drops.

The Fix: To maintain torque at high speeds, you need to optimize the drive voltage (increase it) and select a motor with low inductance.

Understanding this curve ensures your machine doesn't stall when accelerating.

6. Phase Count: 2-Phase vs. 3-Phase

Does phase count matter? Absolutely.

2-Phase Motors: The market standard. Step angle of 1.8° (or 0.9°). Great for general positioning.

3-Phase Motors: Step angle of 1.2°. They offer smoother operation and lower vibration.

For applications requiring ultra-smooth motion or higher torque density, HDBMOTOR's 3-phase solutions are the superior choice.

7. No-Load Starting Frequency

If your application requires frequent, instant starts and stops at speeds over 1000 RPM, you must consider the "Pull-in Rate" or no-load starting frequency.

Hybrid or Permanent Magnet motors generally offer better starting characteristics. Failing to account for this can lead to "lost steps" or stalling during startup.

Need Customization? HDBMOTOR Has You Covered

Standard off-the-shelf motors don't always fit unique machinery. Unlike generic suppliers, HDBMOTOR specializes in custom engineering.

Custom Shaft Lengths & Diameters

Specific Cabling & Connectors

Tailored Winding Characteristics

[Contact HDBMOTOR Engineering Team Today] to discuss your project requirements.

Recommended Articles:

Do Stepper Motors Get Hot? 7 Powerful Causes and Solutions

Stepper Motor Continuous Jitter When Returning to Origin: 7 Common

Introduction to Brushless DC Motors: Powerful Working Principles & Applications