Motor Torque Calculation Formula: Complete Guide with Practical Example

The Motor Torque Calculation Formula is essential for engineers working with servo motors, stepper motors, and general electric motors. Whether you are designing automation equipment, CNC machinery, robotics, or motion control systems, understanding torque requirements ensures the selected motor can achieve the target acceleration, speed, and load performance.

This article explains the Motor Torque Calculation Formula in clear steps, using a real calculation example. It also covers related formulas, such as the servo motor torque calculation formula, the electric motor torque calculation formula, and the general formula for calculating torque of a motor. These principles apply when evaluating NEMA stepper motors, servo drives, industrial DC motors, or any motor-driven mechanism.

1. Why the Motor Torque Calculation Formula Matters

Every motor must produce enough torque to:

accelerate a rotating mass

overcome friction

maintain its rated speed

reach the target speed of a motor within a required time

support mechanical loads safely

If torque is insufficient, the motor may stall, fail to reach speed, or operate inefficiently. This is why engineers rely on the Motor Torque Calculation Formula before selecting a suitable motor.

2. Standard Formula for Calculating Torque of a Motor

The universal formula for calculating torque of a motor during acceleration is:

Torque = Moment of inertia × Angular acceleration

This same method applies to:

servo motor torque calculation formula

electric motor torque calculation formula

stepper and brushless motor torque estimation

To demonstrate how this works, we use a real calculation problem below.

3. Real Calculation Example

Problem:

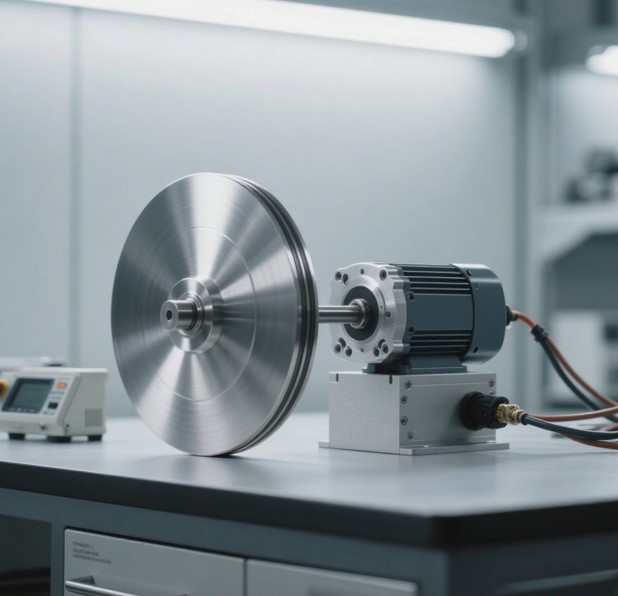

What torque is required to accelerate a flywheel (50 g, radius 4 cm) from 0 to 3000 rpm in 1 second?

This is a typical engineering motor torque calculation formula problem used when sizing motors for rotating loads.

Step 1: Unit Conversion

Mass: 50 g → 0.05 kg

Radius: 4 cm → 0.04 m

Final speed: 3000 rpm → approx. 314.159 rad/s

Initial speed: 0 rad/s

Time: 1 second

Step 2: Moment of Inertia

Assume the flywheel is a uniform solid disk.

Moment of inertia = 1/2 × mass × radius²

radius² = 0.04 × 0.04 = 0.0016

mass × radius² = 0.05 × 0.0016 = 0.00008

moment of inertia = 0.5 × 0.00008 = 0.00004 kg·m²

Step 3: Angular Acceleration

Angular acceleration = change in angular speed ÷ time

Angular acceleration ≈ 314.159 rad/s²

Step 4: Torque Calculation

Torque = 0.00004 × 314.159

Torque ≈ 0.0126 N·m

Also:

0.0126 N·m = 12.6 mN·m

This means the motor must deliver at least 12.6 mN·m to meet the required acceleration.

4. Engineering Interpretation

In real applications, additional torque is needed for:

friction

air resistance

mechanical coupling

safety factors

peak-load startup conditions

Therefore, engineers typically add 20–50% torque margin depending on system requirements.

This principle is used in:

servo motor torque calculation formula for high-speed positioning

electric motor torque calculation formula for industrial drives

stepper motor load estimation

inertia matching for servo drive systems

5. Where the Motor Torque Calculation Formula Is Commonly Used

This formula is widely used in industries involving:

CNC routers and laser machines

3D printers and automation lines

robotics joints

conveyor systems

precision motion control equipment

Engineers rely on these torque calculations to ensure the chosen motor can reach both the acceleration rate and the final rated speed safely.

6. Summary

The Motor Torque Calculation Formula provides a universal way to determine the torque needed for accelerating any rotating load. Understanding this formula helps you choose the right motor, ensure reliable operation, and optimize performance across servo motors, stepper motors, and electric motors.