What Is a NEMA 17 Stepper Motor? Complete Guide for Industrial Precision

A NEMA 17 stepper motor is one of the most widely used motion-control motors in automation, robotics, and precision manufacturing. For companies seeking stable, accurate, and repeatable motion—such as 3D printing, CNC equipment, laboratory automation, textile machinery, camera sliders, semiconductor machines, and medical devices—the NEMA 17 stepper motor offers exceptional performance at a low cost. As a global manufacturer of high-precision motors, HDBMOTOR provides a full range of NEMA 17 models tailored to industrial environments.

What Is a NEMA 17 Stepper Motor?

The term NEMA 17 stepper motor refers to a stepper motor size standardized by NEMA (National Electrical Manufacturers Association). “17” represents a 1.7 × 1.7 inch (about 42 × 42 mm) faceplate size. This standard ensures compatibility with mounts, brackets, and industrial machine designs across many industries.

A stepper motor operates by receiving discrete electrical pulses. Every pulse drives the motor to rotate a fixed step angle, allowing extremely accurate positioning without requiring encoders. This makes stepper motors ideal for cost-efficient precision systems.

Key Features of a NEMA 17 Stepper Motor

Compared with other motor types, a NEMA 17 stepper motor provides several advantages:

1. High Positioning Accuracy

Most models offer step angles such as 1.8°, 0.9°, or microstepping at even smaller increments when driven by a stepper driver.

2. Compact But Strong Torque

Despite its small size, the NEMA 17 produces 30–60 N·cm torque depending on rotor design, making it suitable for high-precision loads.

3. Easy Machine Integration

The 42 mm body frame aligns with standard industrial machine mounts and brackets.

4. Long Service Life

Because stepper motors do not rely on brushes, the lifespan is significantly longer and maintenance is minimal.

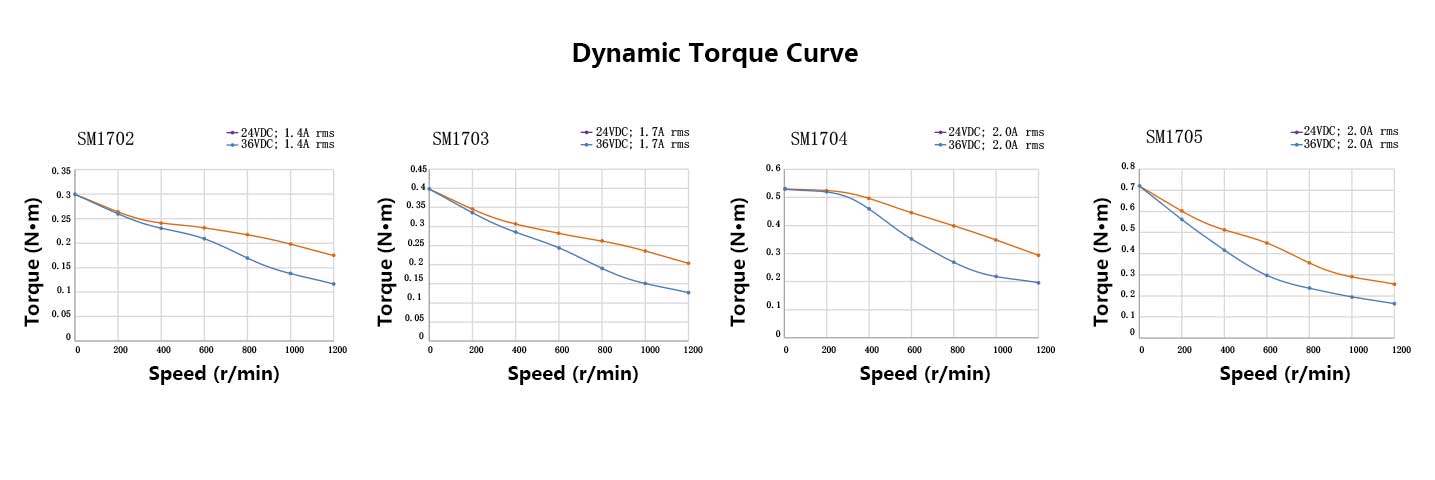

5. Compatible With Many Drivers

A NEMA 17 stepper motor can be paired with a variety of modern stepper drivers for improved torque, smoothness, and speed control.

Stepper Motor NEMA 17 vs Other Frame Sizes

When choosing between multiple stepper motor sizes—such as NEMA 14, NEMA 23, or NEMA 34—the stepper motor NEMA 17 offers a balanced combination of torque, size, and cost.

NEMA 14 → smaller, low torque

NEMA 23 → larger, higher torque

NEMA 17 → ideal middle range for compact precision machines

This balance explains why equipment manufacturers across 3D printing, medical automation, and robotics commonly choose the motor stepper NEMA 17 size.

NEMA 17 Stepper Motor Dimensions

The standard front face is 42 × 42 mm, but the body length varies depending on torque:

Short body: 34 mm – 40 mm

Medium body: 40 mm – 48 mm

Long body: 48 mm – 60+ mm

Shaft types can include:

Round shaft

D-cut shaft

Dual shaft

Integrated leadscrew (for linear actuators)

These NEMA 17 stepper motor dimensions help engineers decide which version best fits their mechanical design.

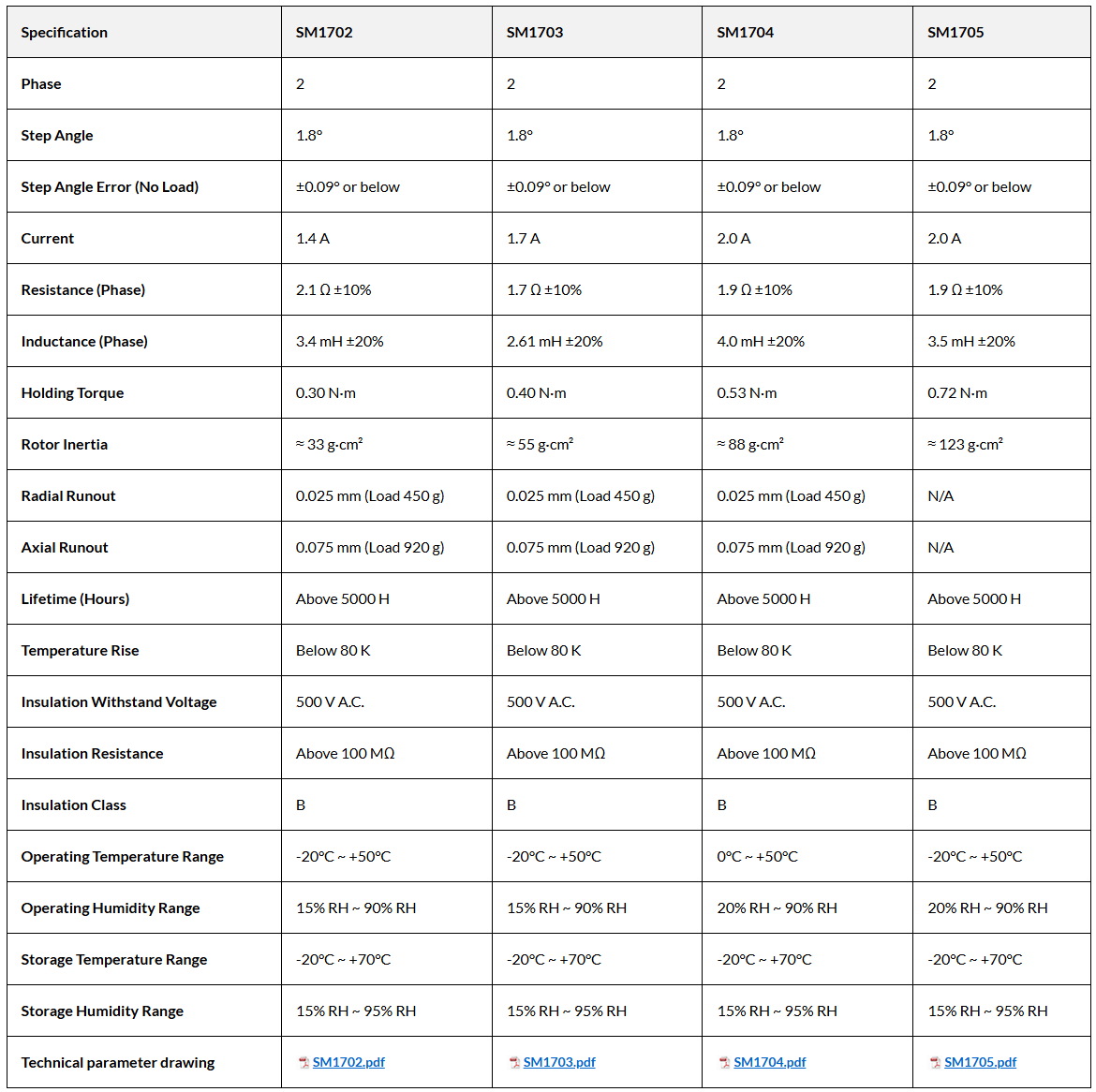

NEMA 17 Stepper Motor Datasheet Overview

Different models have different specifications, but a typical NEMA 17 stepper motor datasheet includes:

Step angle: 1.8° or 0.9°

Rated current: 1.2–2.0 A

Resistance: 1–3 Ω

Holding torque: 30–60 N·cm

Rotor inertia: 45–60 g·cm²

Shaft length: 18–24 mm

For specialized industries such as semiconductor automation or laboratory analyzers, HDBMOTOR can supply custom datasheet parameters including IP protection levels, high-temperature coils, and low-noise rotor structures.

Industry Applications of the NEMA 17 Stepper Motor

Because of its reliability and precision, the NEMA 17 stepper motor is used in:

Manufacturing & Automation

PCB assembly equipment

Automated screw-driving systems

Medical & Laboratory Devices

Syringe pumps

Liquid handling systems

Micro-dispensing machines

Robotics

Robotic arms

Pan-tilt camera systems

Small AGV/AMR modules

3D Printing & Prototyping

X/Y/Z axis movement

Extruder motors

Textile & Packaging Machines

Yarn tension control

Precision feeding systems

HDBMOTOR designs optimized NEMA 17 versions for harsh environments, continuous duty, and high-temperature industrial production lines.

Why Choose HDB MOTOR NEMA 17 Stepper Motors?

Industrial-grade coil materials

Low noise and low vibration design

Optional gearboxes, encoders, and custom shafts

OEM/ODM engineering support

Fast delivery for mass-production orders

Whether you need a simple off-the-shelf model or a fully customized solution, HDBMOTOR provides long-life, high-precision NEMA 17 motors for demanding automation systems.

Conclusion

A NEMA 17 stepper motor is a highly versatile and widely adopted motor size used across robotics, manufacturing, medical devices, 3D printing, and precision automation. With its perfect balance of torque, compact size, and accuracy, it remains one of the most dependable choices for engineers worldwide. HDBMOTOR continues to deliver industry-grade NEMA 17 solutions with comprehensive datasheets and customizable features for professional applications.