What Is a Stepper Motor? A Comprehensive Guide

If you’re wondering what is a stepper motor and how it functions, you’re in the right place. Stepper motors are widely used in automation and robotics for their precise control of position and speed. This article will explain what a stepper motor is, how it works, its types, control methods, and applications.

What Is a Stepper Motor?

A stepper motor is an open-loop control device that converts electrical pulse signals into angular or linear displacement. By controlling the sequence, frequency, and number of pulses applied to the motor coils, you can precisely control the motor’s direction, speed, and rotation angle. When combined with linear actuators or gearboxes, stepper motors can achieve complex and accurate linear motion control.

Stepper Motor Structure

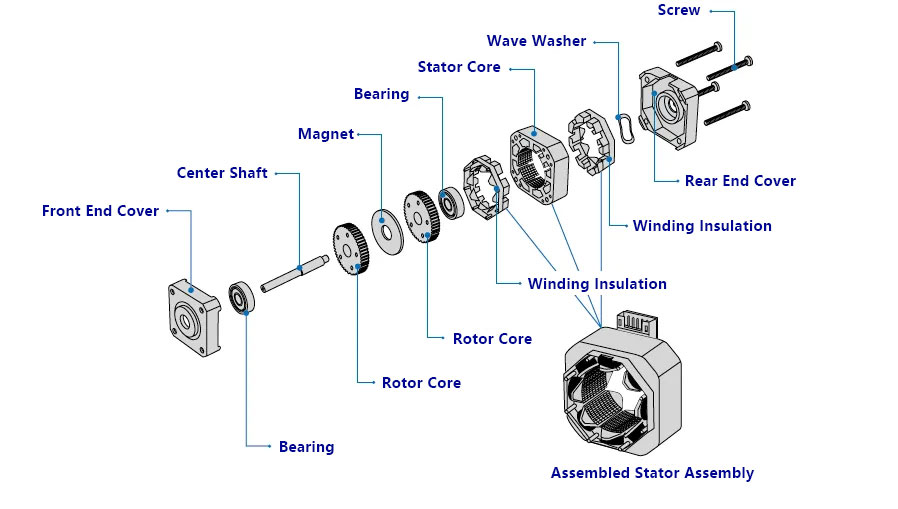

A typical stepper motor consists of front and rear end covers, bearings, a central shaft, rotor core, stator core, stator assembly, wave washers, and screws. Also known as a "stepper," it operates on electromagnetic principles by converting electrical energy into mechanical motion. The coils wrapped around the stator’s tooth slots are called windings or phases.

Stepper Motor Structure

Internal Assembly Diagram of Stepper Motor

How Does a Stepper Motor Work?

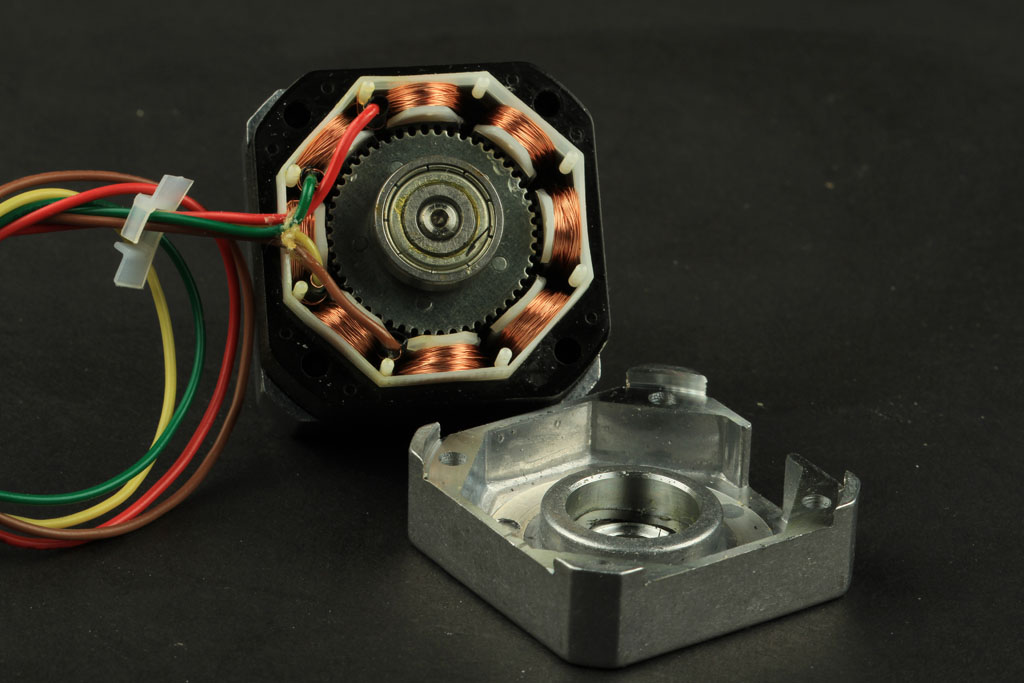

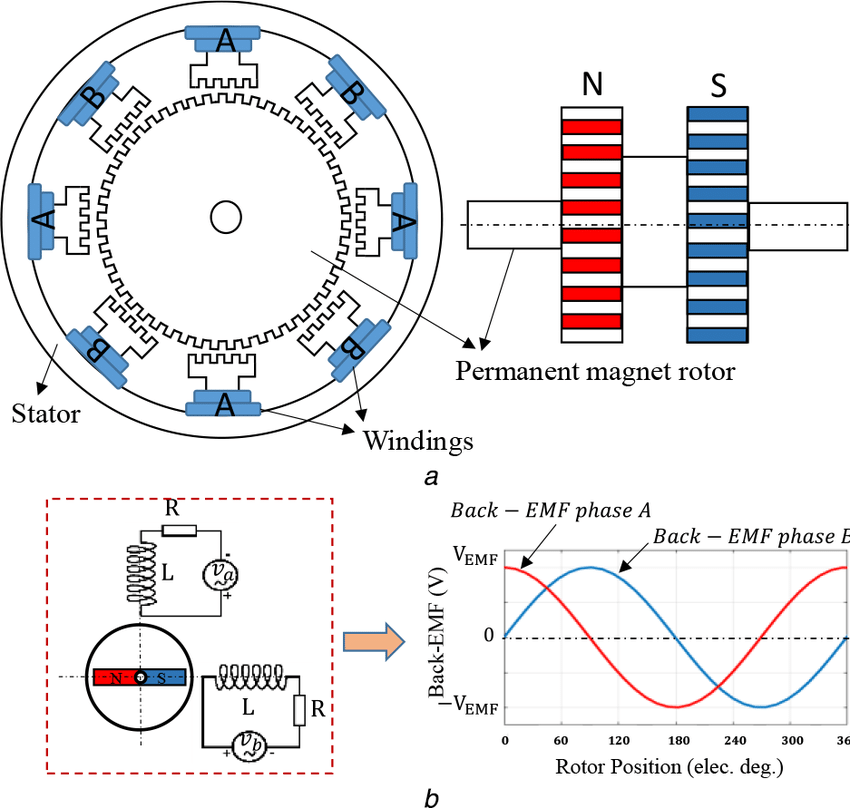

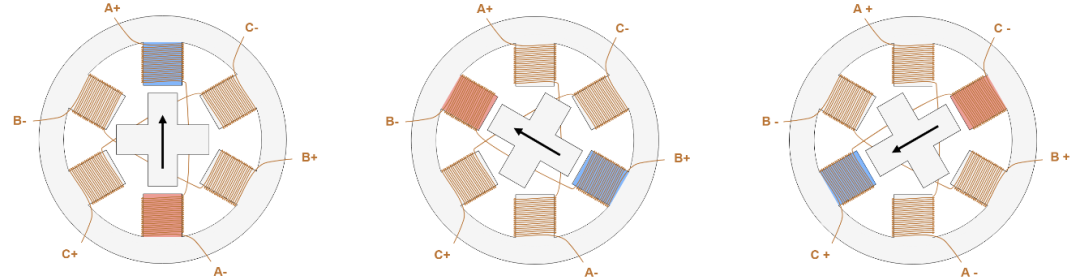

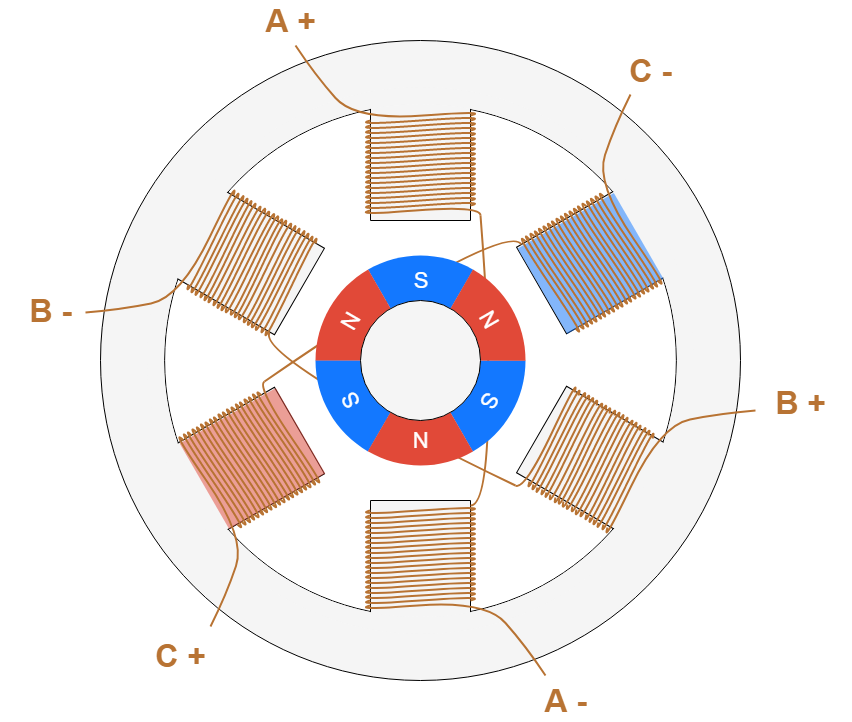

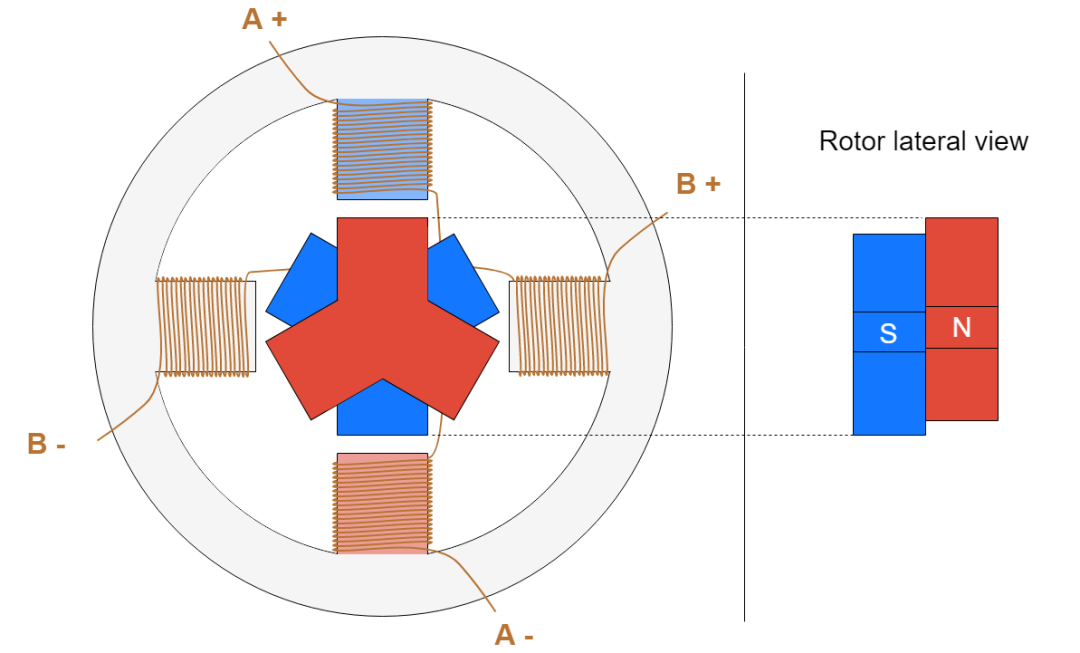

A stepper motor has two main parts: the fixed stator with coil-wrapped gear-like teeth, and the rotating rotor, which can be a permanent magnet or variable reluctance iron core. When power is applied to a stator winding, it creates a magnetic field; the rotor aligns with this field. By sequentially energizing the stator windings, the rotor moves in precise steps to the desired position.

Schematic Diagram

Simplified Internal Schematic

For example, energizing coil A aligns the rotor with its magnetic field; then coil B energizes, causing the rotor to rotate 60° clockwise to align with coil B’s field; coil C follows similarly. The color-coded teeth on the stator indicate the magnetic field directions.

Rotation Process

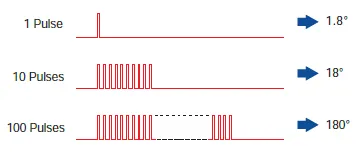

Stepper motors are special synchronous motors driven by pulse currents, moving the rotor in fixed step angles. The number of rotor poles determines the step angle. Each input pulse causes the rotor to rotate one step; multiple pulses correspond to multiple steps.

For instance, a 1.8° two-phase stepper motor remains locked when both phases are energized, providing a holding torque. Reversing the current in one phase causes the rotor to rotate one step (1.8°) in a set direction. Sequentially energizing the coils allows continuous, highly accurate rotation. Such a motor requires 200 steps for a full 360° rotation.

Types of Stepper Motors

Stepper motors are categorized by stator phases: single-phase, two-phase, three-phase, four-phase, and five-phase.

Based on rotor structure, the main types include:

Variable Reluctance (VR) Stepper Motors:

Made of high magnetic permeability materials with toothed rotor and stator. Cost-effective, small step angles (~1.5°), usually three-phase, large torque output but poorer dynamic performance with higher noise and vibration.

Permanent Magnet (PM) Stepper Motors:

Feature multi-pole cylindrical permanent magnet rotors and toothed stators. Use magnetic attraction and repulsion for rotation. Good dynamic performance and high output, but larger step angles (7.5° or 15°), typically two-phase, smaller torque and size.

Permanent Magnet Stepper Motor

Hybrid (HB) Stepper Motors:

Combine VR and PM advantages, available in two-phase (1.8° step angle) and five-phase (0.72° step angle) versions. Use rare-earth magnet toothed rotors and toothed stators. High performance, small step angles, strong output, and good dynamic response. Widely used in computers and precision equipment.

Hybrid Stepper Motor

How Is a Stepper Motor Controlled?

Stepper motors cannot be driven directly by DC voltage; they require pulse signals. The motor’s rotation angle is proportional to the number of pulses applied by the driver, while the rotation speed is proportional to pulse frequency.

Angle vs. Pulse Count: More pulses cause more rotation steps.

Angle-to-Pulse Relationship

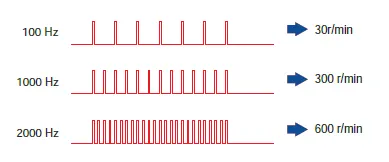

Speed vs. Pulse Frequency: Higher frequencies increase speed in full-step mode.

Speed-to-Pulse Relationship

Control is typically achieved using dedicated driver ICs. Simple applications use low-cost drivers, whereas high-precision control demands advanced drivers to unlock additional control features.

What Is a Stepper Motor Used For?

Stepper motors are widely used where precise angular positioning is critical. Common applications include:

Optical drives: moving read heads

Printers: controlling print head positioning

Automated warehouse robots: accurate object handling

CNC machines: spindle positioning

By precisely controlling pulse counts and frequencies, stepper motors enable accurate rotation and positioning, making them essential in industrial automation. Understanding what is a stepper motor and its control principles is vital for engineers and beginners alike.

Our company offers various types of stepper motors, including single-phase, two-phase, three-phase, four-phase, and five-phase models. We also provide customized solutions based on customers’ specific requirements. Not all models are displayed on our website, so please contact us directly for more detailed information, inquiries, and quotations.

Recommended Articles:

How to Control Stepper Motor Speed

Stepper Motor Continuous Jitter When Returning to Origin

Top 8 Features of Hybrid Stepper Motors You Should Know