Stepper Motor Selection Parameters: 7 Key Factors You Must Know

Understanding the stepper motor selection parameters is crucial for engineers and technicians working in industrial automation and manufacturing. Selecting the right stepper motor involves more than just looking at the drive current; it requires a comprehensive evaluation of factors such as static torque, drive method, drive voltage, and other critical specifications. This guide covers the seven most important parameters to help you choose the ideal stepper motor for your application.

Static Torque of Stepper Motor

Static torque is the torque generated when the rated current energizes the motor’s two-phase coils while the rotor remains stationary. It represents the motor’s ability to hold position against external forces and is similar to the “power” rating in traditional motors. For instance, motors with torque below 0.8 N·m usually correspond to frame sizes from NEMA 8 to NEMA 17. Motors around 1 N·m often use NEMA 23 frames, while larger torque requirements call for NEMA 34, NEMA 42, or bigger.

Stepper Motor Drive Method

The drive method significantly impacts motor performance. Common driving techniques include constant voltage and constant current drives, as well as unipolar and bipolar winding configurations.

Constant Voltage Drive: Requires careful resistance selection to prevent excessive current that could damage the driver.

Constant Current Drive: Used for motors with low resistance and rated currents typically between 1-3 A, requiring specialized drivers for higher currents.

Unipolar Drive: Employs four power transistors with current flowing in one direction per coil, suitable for high-speed applications.

Bipolar Drive: Uses double the transistors allowing current to reverse direction, providing higher torque at low speeds but with more complex circuitry.

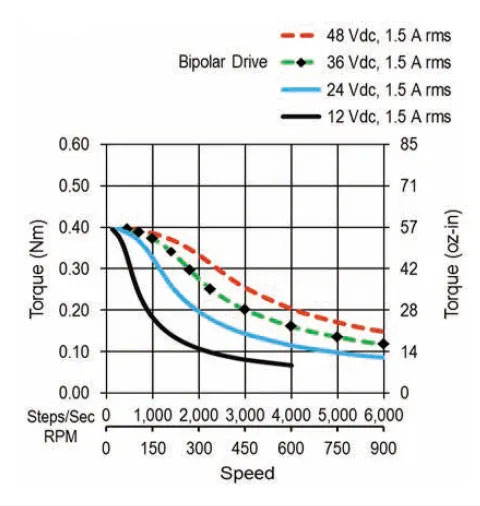

Drive Voltage for Stepper Motors

Drive voltage, the input voltage to the motor driver, varies widely—common options include DC 12V, 24V, 48V and AC 24V, 36V, 110V, and higher. Higher voltages generally improve torque and speed capabilities, especially at elevated speeds.

Drive Current Considerations

Drive current, or phase current, is the current flowing through each motor winding. Even motors with similar sizes and static torque can have different resistance and current ratings.

Stepper Motor Torque Characteristics

The torque-frequency characteristic curve shows how torque decreases as speed increases. Stepper motors deliver high torque at low speeds but lose torque at higher speeds. Adjusting drive voltage, resistance, and inductance can optimize torque output for your application.

Number of Phases in Stepper Motors

The number of phases, typically two or three, affects step angle and smoothness. Two-phase motors usually have step angles of 0.9° or 1.8°, while three-phase motors offer 1.2°. Smaller step angles result in smoother operation, and three-phase motors are preferred in high-speed and high-torque scenarios.

No-load Starting Frequency

Also known as “empty frequency,” this parameter defines the motor’s ability to start without load at a certain speed. Applications requiring frequent starts and stops at speeds around 1000 rpm benefit from motors with high no-load starting frequency, such as permanent magnet or reactive types.

Recommended Articles:

Electric Stepper Motor Terminology