Stepper Drive Advantages

Stepper drive advantages continue to make stepper-based motion systems a preferred choice in industrial automation, CNC machines, packaging equipment, and precision positioning platforms. Despite the rise of servo systems, many engineers still rely on stepper drives for their simplicity, cost efficiency, and predictable behavior—especially when system requirements are well understood.

In real-world applications, most stepper motor problems do not originate from the motor itself, but from incorrect driver selection or configuration. This article explains the key stepper drive advantages from an engineer’s perspective and shows how to apply them correctly to achieve stable, reliable motion while avoiding common pitfalls.

1. Simple Control Architecture and Predictable Motion

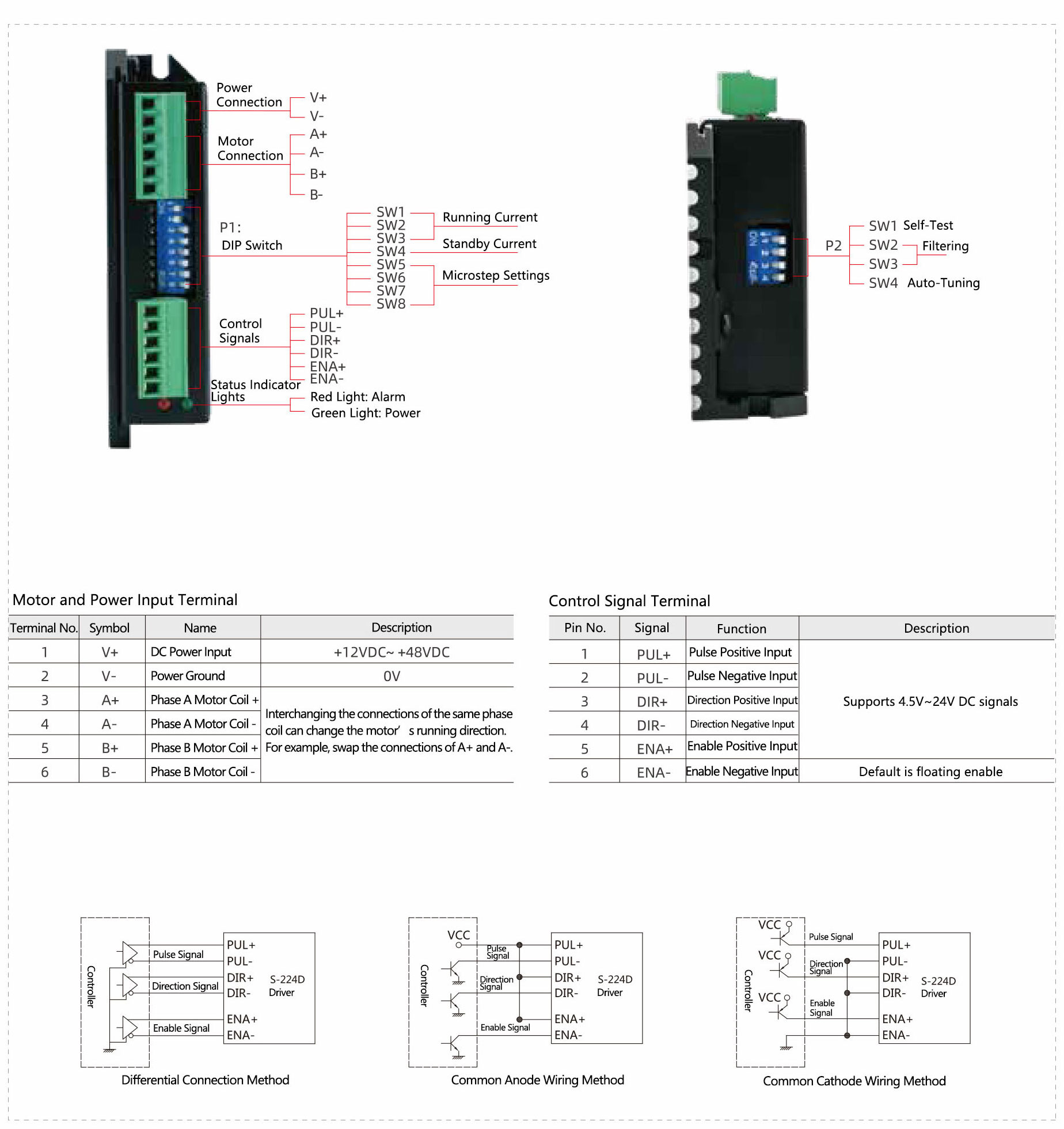

One of the most practical stepper drive advantages is control simplicity. Stepper systems rely on pulse-based positioning rather than closed-loop feedback, making them easy to integrate into PLC- or controller-based automation systems.

For most applications, selecting a stepper motor driver begins with four core parameters:

Supply voltage

Output current

Microstepping resolution

Maximum step pulse frequency

A well-designed stepper motor driver selection ensures the driver can deliver at least 1.4× the motor’s rated phase current, providing enough torque margin under load and during acceleration.

2. Microstepping Improves Smoothness and Reliability

Another key stepper drive advantage is microstepping. Contrary to common belief, microstepping is not primarily about increasing positioning accuracy—it is about improving motion smoothness and reducing mechanical shock.

A properly configured microstepping stepper drive offers:

Lower vibration at low speeds

Reduced resonance and audible noise

Improved system stability

However, excessive microstepping without sufficient voltage or current reduces available torque. In many industrial systems, 1/4 or 1/8 microstepping provides the best balance between smooth motion and usable torque.

3. High Supply Voltage Enhances Performance

A frequent misunderstanding among users is the relationship between rated motor voltage and actual drive voltage. One of the most overlooked stepper drive advantages is effective stepper motor voltage control.

Motor rated voltage only reflects DC conditions at standstill. During motion, inductance and back EMF limit current rise. A higher drive voltage allows the chopper circuit to overcome these effects, maintaining torque at higher speeds.

Without adequate voltage:

Torque drops rapidly

Microstepping becomes ineffective

The system appears underpowered

This is why industrial stepper drives commonly operate at 24V, 36V, or higher.

4. Flexible Current Control Protects the Motor

Modern stepper drives offer advanced current management, including idle current reduction and programmable filtering. These features help reduce heat generation when the motor is holding position.

This is especially important because stepper motors draw near-full current at standstill. Intelligent current control improves thermal stability and extends motor lifespan—another practical stepper drive advantage in continuous-duty applications.

5. Wide Compatibility With Control Signals

Industrial stepper drives are valued for their signal flexibility. Many designs support:

5–24V pulse, direction, and enable signals

Single-pulse or dual-pulse control modes

Configurable alarm outputs

This flexibility simplifies integration across PLCs, motion controllers, and embedded systems without additional interface hardware.

6. Cost-Effective Alternative to Servo Systems

When position feedback is not mandatory, stepper drives provide a significantly more economical solution than servo systems. Engineers often move to servos prematurely due to vibration or noise issues that could be resolved through correct driver configuration.

For speeds below approximately 2000 RPM and applications with predictable loads, stepper drives remain one of the most cost-effective motion solutions available.

7. Proven Reliability in Industrial Environments

Well-designed industrial stepper drive systems perform reliably in demanding environments when proper grounding, filtering, and cable routing are applied.

Features such as DIP-switch configuration for filtering, compact housing, and short delivery cycles make modern stepper drives suitable for both prototyping and mass production.

Practical Advice for Engineers

If your system experiences vibration, noise, missed steps, or overheating, the root cause is often:

Incorrect current or voltage setting

Poor microstepping selection

Mechanical load mismatch

Before changing the motor, review the driver configuration and overall system design. In many cases, correct driver selection resolves performance issues without increasing system cost.

Note that not all driver variants and configurations are always listed online. If you need alternative models, application-specific recommendations, or detailed configuration guidance, leaving an inquiry with your supplier is often the fastest way to obtain accurate technical support.

Final Thoughts

Understanding real stepper drive advantages allows engineers to design simpler, more reliable motion systems without unnecessary complexity or expense. When voltage, current, microstepping, and mechanical load are properly matched, stepper drives continue to deliver excellent performance across a wide range of industrial applications

For related motion control topics, you may also find these helpful: