Ultimate 60BL56-30L2R05-T212 BLDC Motor for Sweeping Robots Revolutionizes Cleaning

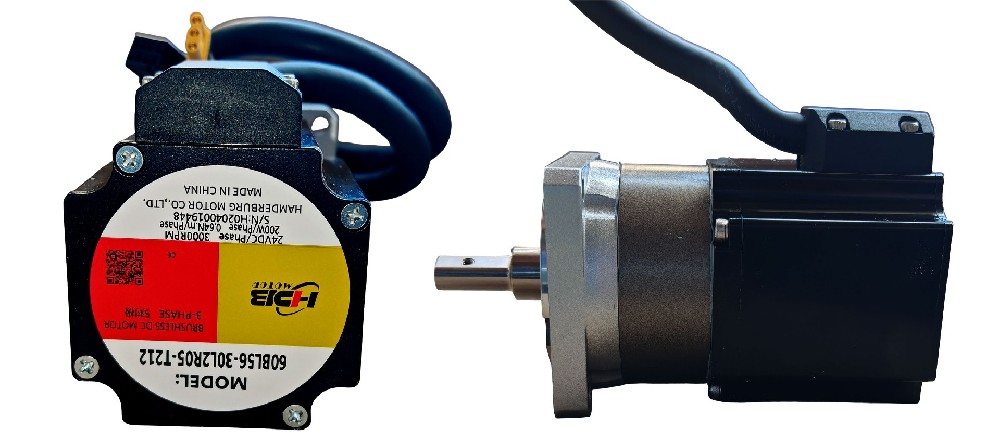

The ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots stands out as a game-changer in commercial cleaning automation. Paired seamlessly with the DBL-2420R driver, this 3-phase brushless DC motor delivers unmatched performance for modern sweeping robots. Designed for heavy-duty tasks, it handles large spaces like warehouses, malls, and offices with precision and power. With 200W rated output and 3000 RPM speed, this motor ensures your robots navigate obstacles effortlessly while maintaining high efficiency.

In today's fast-paced commercial environments, reliable robotics is essential. The ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots addresses key challenges like battery life, torque under load, and quiet operation. Certified RoHS and CE compliant, it's built to last in dusty, demanding conditions.

Key Features of the 60BL56-30L2R05-T212 BLDC Motor

This compact powerhouse measures just 120x76x63mm, making it perfect for robot chassis integration. Here's what sets it apart:

Rated Voltage and Power: Operates at 24-32V DC with 10A rated current, peaking at 31.5A for bursts of strength.

Torque Excellence: Delivers 0.64 Nm rated torque and 1.92 Nm peak, with gearbox-enhanced stall torque up to 40 Nm.

Speed Mastery: 3000 RPM rated, up to 4000 RPM max, controlled precisely via 0-5V analog or PWM input.

Durability Specs: Class B insulation withstands 130°C, winding resistance at 0.159Ω, and backlash efficiency at 90%.

The DBL-2420R driver complements these specs with 0-100% PWM support and multi-speed internal settings, enabling smooth acceleration for robot pathing.

Perfect Pairing: DBL-2420R Driver Integration

No motor shines alone—the DBL-2420R driver is the ideal match for the ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots. This driver handles up to 450W continuous and 500W peaks, matching the motor's demands perfectly.

Key driver benefits include:

Versatile input: 0-5V analog for fine speed tuning, 0-10V PWM for dynamic control.

Protection features: Overcurrent, overtemperature, and short-circuit safeguards.

Efficiency: Hall sensor feedback for closed-loop operation, reducing energy waste.

Together, they achieve 85%+ efficiency, extending robot runtime by hours. Internal speed presets simplify programming for straight-line sweeping or tight turns.

Applications in Commercial Sweeping Robots

Commercial sweeping robots thrive in expansive areas where manual cleaning falls short. The ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots powers drivetrains for superior traction on varied floors—tile, carpet, or concrete.

Real-world uses:

Warehouse Cleaning: 40 Nm stall torque conquers debris piles; 3000 RPM ensures quick coverage.

Mall Navigation: Low noise (60dB) and IP-rated protection handle foot traffic and spills.

Office Floors: Precise control avoids furniture; 20,000-hour lifespan cuts maintenance.

BLDC motors like this outperform brushed alternatives with no sparks, longer life, and higher speeds up to 100,000 RPM in optimized designs.

Internally, pair with our high-torque gearbox options for even more power.

Performance Parameters Breakdown

Dive deeper into the specs driving excellence:

| Parameter | Motor Value | Driver Support |

|---|---|---|

| Rated Power | 200W / 10A | Up to 450W |

| Max Speed | 4000 RPM | 0-5000 RPM adjustable |

| Rated Torque | 0.64 Nm | Gear output: 5.1 Nm |

| Peak Torque | 1.92 Nm | STALL: 40 Nm |

| Efficiency | 85% (RHO-SiC85%) | PWM controlled |

| Operating Temp | -30°C to 70°C | Full range |

| Noise Level | <60dB | Optimized |

| Lifetime | 20,000 Hours | Continuous duty |

These figures ensure robots sweep 5000+ sqm per charge.

Why Choose This Ultimate BLDC Solution?

Investing in the ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots means future-proofing your fleet. Benefits include:

Cost Savings: 3x longer life than brushed motors; lower energy use.

Superior Control: Servo-like precision for LiDAR mapping and obstacle avoidance.

Scalability: Stack multiples for differential drive in advanced bots.

Eco-Friendly: High efficiency aligns with green building standards.

Users report 30% faster cleaning cycles and halved downtime.

Installation and Maintenance Tips

Getting started is straightforward:

Mount motor securely in robot base.

Wire DBL-2420R: VCC/GND to battery, PWM/analog to controller.

Calibrate speeds via Hall sensors.

Test under load for torque mapping.

Maintenance is minimal—clean vents quarterly, check bearings yearly. This setup's IP65-level protection shrugs off dust.

Future of Sweeping Robots with Advanced BLDC

As AI advances, expect ultimate 60BL56-30L2R05-T212 BLDC motor for sweeping robots integrations with 5G fleets. Power Motor notes BLDCs reshaping vacuums with 80%+ efficiency. Your commercial cleaning operations will never be the same.

Ready to upgrade? Contact us for samples.

Recommended Articles:

Working Principle of a Stepper Motor Driver